Collision repair standards have undergone a remarkable transformation driven by technological advancements and safety concerns. Initially focused on basic manual repairs, the industry now demands higher precision due to complex vehicle designs and integrated safety features. Modern equipment like CAD systems, robotic welding, and laser measurement devices ensure accurate and safe repairs, restoring both structural integrity and aesthetic appeal while meeting stringent standards. These advanced technologies revolutionize collision repair by enhancing speed, accuracy, and quality, ultimately fostering excellence and boosting customer satisfaction.

Collision repair standards have evolved significantly over time, driven by safety concerns, consumer expectations, and technological advancements. To meet these changing demands, the automotive industry has seen a shift towards incorporating advanced equipment in collision repair processes. This article explores the evolution of collision repair standards, highlights how modern equipment enhances precision and efficiency, and discusses the numerous benefits of integrating contemporary technology into the collision repair landscape.

- The Evolution of Collision Repair Standards

- Advanced Equipment: Enhancing Precision and Efficiency

- Benefits of Incorporating Modern Technology in Collision Repair

The Evolution of Collision Repair Standards

Collision repair standards have undergone a remarkable evolution over the years, driven by advancements in technology and safety requirements. In the past, basic repairs like straightening fenders and replacing parts were the primary focus, often conducted with manual tools and minimal guidance. However, as vehicle designs became more complex and safety features integrated, the industry demanded higher-quality repairs that match the precision and strength of original equipment.

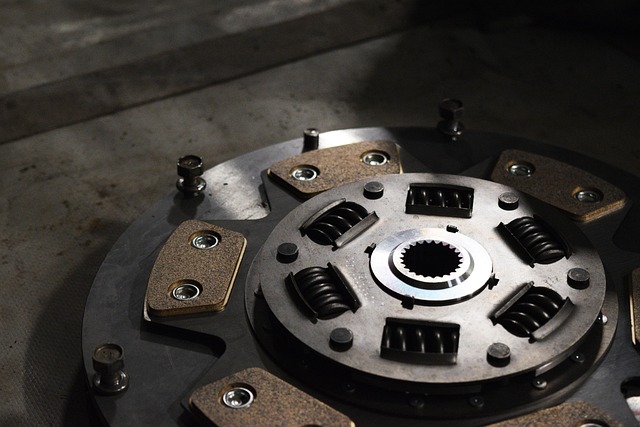

This shift led to the implementation of advanced equipment in collision repair facilities. Modern tools like computer-aided design (CAD) systems, robotic welding machines, and laser measurement devices enable technicians to perform precise vehicle dent repair, fender repair, and car damage repair with unparalleled accuracy. Such advancements not only ensure better aesthetics but also enhance safety, as they restore structural integrity and meet stringent collision repair standards.

Advanced Equipment: Enhancing Precision and Efficiency

In the realm of collision repair standards, advanced equipment plays a pivotal role in achieving precision and efficiency. Modern collision repair shops rely on sophisticated technology to ensure that every component of a damaged vehicle is accurately assessed and meticulously repaired. These tools include high-tech sensors, computer-aided design (CAD) software, and robotic systems that can precisely measure and adjust car bodywork services. With such advanced equipment, technicians are able to work with greater speed and accuracy, ensuring that the vehicle not only looks its best but also performs optimally.

The integration of advanced equipment in collision repair shops has revolutionized automotive repair processes. By employing these technologies, repair facilities can reduce the time required for repairs while maintaining high-quality standards. This not only benefits customers by expediting their vehicle’s return but also ensures that every collision repair is executed with meticulous care and attention to detail. As a result, advanced equipment has become an indispensable aspect of collision repair standards, fostering a new level of excellence in car bodywork services.

Benefits of Incorporating Modern Technology in Collision Repair

Incorporating modern technology into collision repair processes offers numerous advantages that significantly enhance both efficiency and quality. Advanced equipment allows for more precise measurements and calculations, ensuring that every component of the car bodywork is accurately assessed and repaired. This level of precision leads to better alignment and fitment, resulting in higher customer satisfaction. For instance, computer-aided design (CAD) systems enable technicians to plan repairs with laser accuracy, minimizing errors often associated with manual measuring.

Moreover, contemporary technology streamlines auto painting processes. Automated painting systems reduce the risk of human error while ensuring a consistent, high-quality finish. These innovations also minimize the environmental impact by controlling paint application and reducing waste. Modern collision repair facilities that embrace these advancements not only meet but exceed industry standards, setting new benchmarks for car collision repair.

Collision repair standards have evolved to incorporate advanced equipment due to the increasing demand for precision, efficiency, and superior vehicle restoration. Modern technology enables collision repair professionals to achieve intricate details, reduce downtime, and ensure structural integrity. By adopting these innovations, repair shops not only meet rising customer expectations but also contribute to safer and more sustainable transportation, solidifying the importance of staying abreast of industry advancements in collision repair standards.