Electric and hybrid vehicles present unique challenges for collision repair due to their specialized electrical systems, high-voltage batteries, and advanced electronics. Collision repair standards are evolving to ensure integrity of EV systems, safety, and functionality after accidents. ISO and ISA guidelines promote eco-friendly practices and require technicians with specialized training in battery systems and complex electrical components, adhering to strict safety protocols for high-voltage systems.

In the evolving automotive landscape, electric and hybrid vehicles (EVs/HVs) present distinct collision repair challenges. This article explores industry standards aimed at ensuring sustainable and safe EV/HV repairs. We delve into the unique complexities of repairing these advanced vehicles, considering their sophisticated electrical systems and safety features. Understanding how these factors influence collision repair practices is crucial for professionals navigating this evolving sector. By examining current standards, we highlight best practices that balance environmental considerations with high-tech repair techniques.

- Understanding Unique Challenges in Electric Vehicle Repairs

- Hybrid Vehicle Safety Features and Their Impact on Collision Repair

- Industry Standards for Sustainable and Safe Electric/Hybrid Collision Repair Practices

Understanding Unique Challenges in Electric Vehicle Repairs

Electric and hybrid vehicles present unique challenges when it comes to collision repair standards. Unlike conventional internal combustion engine (ICE) vehicles, these cars have specialized electrical systems, high-voltage batteries, and sophisticated electronics that require meticulous handling during the repair process. Traditional frame straightening techniques might not be applicable without risking damage to sensitive components, making specialized tools and training crucial for effective car bodywork services.

The complexity of electric vehicle (EV) repairs demands a deep understanding of their unique construction and safety features. For instance, when conducting frame straightening on an EV, technicians must consider the location and integrity of battery packs and electrical systems. Moreover, collision repair professionals need to be adept at using advanced diagnostic tools to accurately assess damage and ensure that all components, from sensors to motors, function optimally after repairs, thus enhancing overall vehicle safety and performance.

Hybrid Vehicle Safety Features and Their Impact on Collision Repair

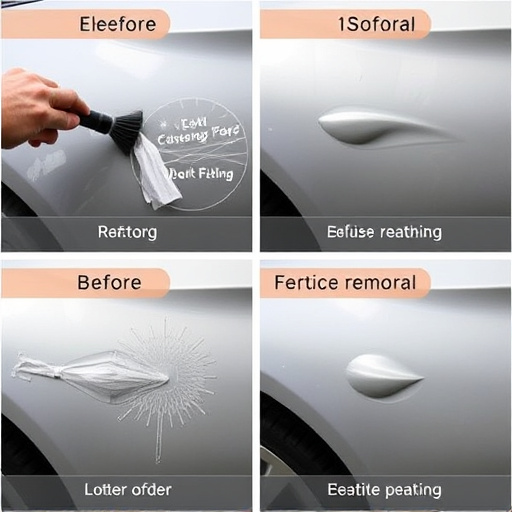

Hybrid vehicles are equipped with a unique suite of safety features designed to enhance driver protection and reduce the impact of collisions. These advanced systems play a pivotal role in shaping collision repair standards for electric and hybrid cars, adding complexity and specific considerations for technicians. Features like regenerative braking, battery management systems, and sophisticated airbag mechanisms require specialized knowledge and tools for safe and effective repairs.

When addressing car collision repair for hybrids, understanding these safety mechanisms is crucial. Auto maintenance professionals must be adept at handling high-voltage components, ensuring proper disposal of hazardous materials, and calibrating sensor systems accurately. The integration of electric powertrains necessitates precise adjustments to maintain vehicle performance and safety standards after an accident, setting a higher bar for collision repair compared to traditional gas-powered vehicles.

Industry Standards for Sustainable and Safe Electric/Hybrid Collision Repair Practices

In the evolving landscape of automotive repair, collision repair standards for electric and hybrid vehicles have become a focal point, driving sustainable and safe practices across the industry. These standards, pioneered by organizations like ISA (International Standards Organization) and ISO (International Organization for Standardization), emphasize eco-friendly material handling and disposal methods. Specialized training and certifications are now crucial for technicians to ensure they’re equipped to handle the unique aspects of repairing these advanced vehicles, including their intricate battery systems and complex electrical architectures.

Beyond environmental considerations, safety remains paramount. Collision centers offering vehicle repair services for electric and hybrid cars must adhere to stringent regulations designed to mitigate risks associated with high-voltage systems. This includes implementing robust protocol for personal protective equipment (PPE), grounding procedures, and de-energy practices to minimize the risk of electrical hazards during repair processes. Such commitment to industry standards not only ensures top-tier collision repair but also fosters a safer environment for technicians and customers alike.

Electric and hybrid vehicles present unique challenges in collision repair due to their advanced technology and safety systems. Understanding these intricacies is vital for ensuring sustainable and safe repair practices. By adhering to industry standards, professionals can effectively navigate the complexities of these vehicles, promoting a greener and safer automotive landscape. Collision repair standards for electric and hybrid vehicles are evolving to meet the demands of this growing market, fostering innovation and responsible vehicle care.