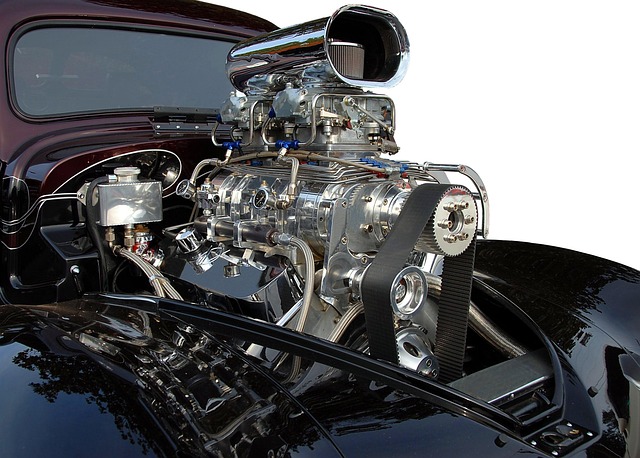

Collision repair standards are vital for auto body technicians, offering detailed procedures, advanced tools, and safety protocols to ensure accurate panel fit and alignment during vehicle restoration. These standards guide professionals through precise measurements and seamless integration of replacement parts, prioritizing customer satisfaction and structural integrity. Proper alignment involves laser measurement tools and 3D scanners for highly accurate assessments, with skilled technicians making subtle adjustments for a flawless finish in processes like fender repair and car scratch repair. Maintaining consistent collision repair standards through structured approaches, regular staff training, and quality checks ensures optimal functionality and a sleek finish, fostering superior customer satisfaction.

Collision repair standards are essential for achieving precise panel fit and alignment, ensuring vehicles return to their pre-accident condition. This comprehensive guide explores the fundamental principles behind these standards, delving into key factors that guarantee accurate repairs. We’ll uncover best practices for collision centers, emphasizing consistent standards to maintain quality and safety. By understanding and adhering to these guidelines, professionals can deliver top-notch results, fostering customer satisfaction in the post-repair journey.

- Understanding Collision Repair Standards: The Foundation for Accurate Panel Fit

- Key Factors in Ensuring Proper Alignment During Repair Process

- Best Practices for Maintaining Consistent Standards in Collision Centers

Understanding Collision Repair Standards: The Foundation for Accurate Panel Fit

Collision repair standards are the cornerstone of ensuring accurate panel fit and alignment in auto body repair. These standards act as a comprehensive guide for technicians, defining the processes, techniques, and specifications required to restore vehicles to their pre-accident condition. By adhering to these guidelines, professionals can achieve precise measurements, proper material handling, and seamless integration of replacement parts.

Understanding collision repair standards involves recognizing the importance of detailed procedures, advanced tools, and meticulous attention to detail. These standards not only cover the technical aspects but also emphasize safety protocols, environmental considerations, and quality control measures. By embracing these practices, auto body repair shops can deliver top-notch services, ensuring customer satisfaction and maintaining the vehicle’s structural integrity through expert vehicle dent repair and collision repair processes.

Key Factors in Ensuring Proper Alignment During Repair Process

Proper alignment is a cornerstone of successful collision repair, ensuring that all components of the vehicle are precisely restored to their original specifications. Several key factors play a pivotal role in achieving this crucial goal. Firstly, advanced equipment such as laser measurement tools and 3D scanners offer highly accurate assessments, providing precise data points for reference during the repair process. These technologies ensure that each panel is positioned with microscopic precision, minimizing the risk of misalignment.

Secondly, the expertise and experience of skilled technicians are indispensable. Trained professionals understand the intricate details of vehicle design and have the ability to make subtle adjustments with expert hands. They visually inspect panels, identify unique features, and make manual fine-tunings when necessary, resulting in a seamless fusion of repaired and original components—a testament to their artistry in car restoration, often reflected in the sleek finish and optimal functionality of fender repair and car scratch repair outcomes.

Best Practices for Maintaining Consistent Standards in Collision Centers

Maintaining consistent standards in collision centers is paramount to achieving accurate panel fit and alignment. To ensure quality control, collision repair facilities should implement a systematic approach that starts with well-defined processes and procedures. Regular staff training on the latest techniques and technologies for vehicle paint repair and auto dent repair is essential. This includes staying updated with industry best practices and utilizing advanced tools designed to enhance precision during car body shop operations.

Standardized quality checks at every stage of the repair process are crucial. This involves thorough inspections using high-resolution cameras and specialized lighting to detect even subtle misalignments or paint imperfections. By fostering a culture of continuous improvement, collision centers can maintain consistent standards, resulting in superior customer satisfaction and reduced repaint rates.

Collision repair standards are vital for achieving precise panel fit and alignment, ensuring vehicles return to their pre-accident condition. By understanding these standards, employing key factors like specialized training and high-quality tools, and adopting best practices such as consistent measurement techniques and quality control checks, collision centers can maintain excellence in their repairs. Adhering to these guidelines fosters customer satisfaction by delivering accurately aligned and fit panels, ultimately enhancing the overall reputation of the collision repair industry.